Search for the supplies that you need here:

DMF Support and Documentations Available | |

WHO-GMP Certified Good Manufacturing Practice Certified by World Health Organization |  WC, Written Confirmation for Active Substance to be imported into European Union (EU). |

Cellulose Acetate Ph Eur BP USP NF IP Manufacturers

Anmol Chemicals is a manufacturer supplier exporter of Cellulose Acetate and it offers materials as per IP BP EP Ph Eur USP NF JP FCC Food Grade as per the the latest monograph at best prices. Anmol Chemicals Group, established in 1976, is the pioneer manufacturer of Specialty Chemicals, Pharmaceutical Excipients, Some API, Food Chemicals in India. Anmol Chemicals Group has manufacturing facilities spread across Western India, representatives in Houston, Chicago USA and Dubai, UAE. We also have toll manufacturing units for processing chemicals in a few countries around the world. We make IP, BP, EP, USP, NF, Ph. Eur., JP, FCC or Food Grade, Analytical Reagent Grade, LR or Laboratory Reagent Grades and Pure Grades of various chemicals. All our items are analyzed to meet the required standards. We can supply the product in grams for your laboratory trial and in tons for your plant scale jobs.

We manufacture Bulk Drugs / API, Excipients, Pharmaceuticals (IP BP USP NF Ph Eur EP JP), Specialty Chemicals (Pure/Reagent), Mineral Fortifiers (FCC). Our manufacturing facility is FDA approved and GLP, cGMP, ISO9001, ISO14001, ISO/IEC 17025, ISO22000, FSSC 22000, ISO45001, FSSAI, Kosher, HALAL, COPP, WHO-GMP certified and Written Confirmation (WC) is available. Solid materials can be customized for particle size, shape, and bulk density. We observe WHO Good Manufacturing Practices and Good Laboratory Practices. We are a government-recognized STAR Export House and "Authorised Economic Operator (AEO)" per Indian Customs.

All technical documents and DMF support available.

Cellulose Acetate SDS of Manufacturers

Synonyms: ----

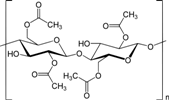

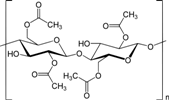

CAS Number: 9004-35-7, Molecular Weight: ----, Chemical Formula: ----, EINECS EC Number: ----, FEMA: ----,

Cellulose Acetate BP Ph Eur Grade Specifications

Ph Eur

Action and use: Excipient.

DEFINITION

Partly or completely O-acetylated cellulose.

Content: 29.0 per cent to 44.8 per cent of acetyl groups (C2H3O) (dried substance) and 90.0 per cent to 110.0 per cent of the acetyl content stated on the label (dried substance).

CHARACTERS

Appearance: White, yellowish-white or greyish-white powder or granules, hygroscopic.

Solubility: Practically insoluble in water, soluble in acetone, in formic acid and in a mixture of equal volumes of methanol and methylene chloride, practically insoluble in alcohol.

IDENTIFICATION

Infrared absorption spectrophotometry.

TESTS

Free acid: Maximum 0.1 per cent, calculated as acetic acid (dried substance).

To 5.00 g in a 250 ml conical flask, add 150 ml of carbon dioxide-free water, insert the stopper, swirl the suspension gently and allow to stand for 3 h. Filter, wash the flask and the filter with carbon dioxide-free water. Combine the filtrate and washings. Add 0.1 ml of PhPh solution. Titrate with 0.01 M sodium hydroxide until a faint pink colour is obtained.

1 ml of 0.01 M sodium hydroxide is equivalent to 0.6005 mg of free acid, calculated as acetic acid.

Heavy metals: Maximum 10 ppm.

2.0 g complies with limit test D. Prepare the standard using 2 ml of lead standard solution (10 ppm Pb) R.

Loss on drying: Maximum 5.0 per cent, determined on 1.000 g by drying in an oven at 105C for 3 h.

Sulphated ash: Maximum 0.1 per cent, determined on 1.0 g.

Microbial contamination: Total viable aerobic count not more than 1000 micro-organisms per gram of which not more than 100 fungi per gram determined by plate count. It complies with the tests for Escherichia coli and Salmonella.

STORAGE

In an airtight container.

The label states the nominal percentage content of acetyl groups.

Cellulose Acetate USP NF Grade Specifications

Cellulose, diacetate CAS 9035-69-2

Cellulose, triacetate CAS 9012-09-3

Cellulose Acetate is partially or completely acetylated cellulose. It contains not less than 29.0 percent and not more than 44.8 percent, by weight, of acetyl (C2H3O) groups, calculated on the dried basis. Its acetyl content is not less than 90.0 percent and not more than 110.0 percent of that indicated on the label.

Packaging and storage: Preserve in tight containers.

Labeling: The labeling states the nominal percentage content of acetyl.

Identification: Prepare a solution of Cellulose Acetate (1 in 10), previously dried, in dioxane. Spread 1 drop of the solution on a sodium chloride plate, place a second sodium chloride plate over it, and spread the specimen between the plates. Separate the plates, heat them both at 105C for 1 hour, and reassemble the dried plates: the IR absorption spectrum exhibits maxima only at the same wavelengths as that of a similar preparation of USP Cellulose Acetate RS, treated in the same manner.

Loss on drying: Dry it at 105C for 3 hours: it loses not more than 5.0% of its weight.

Residue on ignition: not more than 0.1%.

Heavy metals: 0.001%.

Free acid: Transfer about 5 g, accurately weighed, to a 250-mL flask. Add 150 mL of freshly boiled, cooled water, insert the stopper into the flask, swirl the suspension gently, and allow it to stand for 3 hours. Filter through paper, and wash the flask and the filter with water, adding these washings to the filtrate. Add PhPh, and titrate the combined filtrate and washings with 0.01 N sodium hydroxide. Calculate the percentage of free acid in the portion of Cellulose Acetate taken by the formula: 0.06005A/W in which A is the volume, in mL, of 0.01 N sodium hydroxide consumed; and W is the weight, in g, of the Cellulose Acetate taken, calculated on the dried basis. Not more than 0.1%, calculated as acetic acid, is found.

Content of acetyl:

FOR CELLULOSE ACETATE LABELED TO CONTAIN NOT MORE THAN 42.0% OF ACETYL GROUPS:

Transfer about 2 g, accurately weighed, to a 500-mL flask. Add 100 mL of acetone and 5 mL to 10 mL of water to the flask, insert the stopper into the flask, and stir with a magnetic stirrer until solution is complete. Add 30 mL, accurately measured, of 1.0 N sodium hydroxide to the solution, with constant stirring. A finely divided precipitate of regenerated cellulose, free from lumps, is obtained. Insert the stopper into the flask, and stir with a magnetic stirrer for 30 minutes. Add 100 mL of water that has been preheated to 80C, washing down the sides of the flask, stir for 2 minutes, and cool to room temperature. Titrate the excess sodium hydroxide solution with 1.0 N sulfuric acid to a PhPh endpoint. Treat a blank in the same manner. Calculate the percentage of acetyl in the portion of Cellulose Acetate taken by the formula: 4.305(B – A)/W in which B and A are the volumes, in mL, of 1.0 N sulfuric acid consumed by the blank and the Cellulose Acetate, respectively; and W is the weight, in g, of Cellulose Acetate taken, calculated on the dried basis.

FOR CELLULOSE ACETATE LABELED TO CONTAIN MORE THAN 42.0% OF ACETYL GROUPS:

Transfer about 2 g, accurately weighed, to a 500-mL conical flask. Add 30.0 mL of dimethyl sulfoxide and 100 mL of acetone, and stir for 16 hours with the aid of a magnetic stirrer. Pipet 30 mL of 1 N sodium hydroxide slowly into the flask, with constant stirring. Insert the stopper into the flask, and stir for 6 minutes. Allow to stand without stirring for 60 minutes. Resume stirring, and add 100 mL of water that has been preheated to 80C, washing down the sides of the flask. Stir for 2 minutes, and cool to room temperature. Add 4 to 5 drops of PhPh, and titrate the excess sodium hydroxide solution with 0.5 N hydrochloric acid. Add an accurately measured excess of about 0.5 mL of 0.5 N hydrochloric acid. Stir for 5 minutes. Allow to stand for 30 minutes. Titrate with 0.5 N sodium hydroxide to a persistent pink endpoint, using a magnetic stirrer for agitation. Calculate the net number of milliequivalents of sodium hydroxide consumed, and correct this value by use of the average of two blank determinations run concomitantly through the entire procedure. Calculate the percentage of acetyl in the portion of Cellulose Acetate taken by the formula: 4.305n/W in which n is the corrected value of the net number of milliequivalents of sodium hydroxide consumed; and W is the weight, in g, of Cellulose Acetate taken, calculated on the dried basis.

Keywords: Cellulose Acetate IP BP Ph Eur EP USP Analytical Reagent FCC Food Grade CAS Number 9004-35-7 Manufacturer Supplier Exporter Monograph Uses Chemical Molecular Formula Weight.

Manufacturer Supplier Exporter

ANMOL CHEMICALS Private Limited

Representatives in Houston, Chicago and New York, USA

TEL: (OFF) +91 22 23726950, +91 22 23774610, +91 22 23723564

Taloja Navi Mumbai, Banglore, INDIA

e-mail: info@anmol.org

Copyright and Usual Disclaimer is Applicable

Last updated 9-oct-25

Exporters to USA, Canada, UAE, Kuwait, Qatar, Gautemala, Tunisia, Europe, South Africa, Bangladesh, Sri Lanka, Tanzania, Kenya, Egypt, Iraq, Turkey, Israel, Vietnam, Nigeria, Uganda, Brazil, Chile, Argentina, Dubai, UAE, Saudi Arabia, Cameroon, Mexico, Brazil, Chile, Argentina, Korea, Thailand, Malaysia, Indonesia, Jakarta, Australia, China, Germany, France, etc.

Representatives in New York, Houston - Texas, Chicago - Illinois, Los Angeles.

All products are Sold for Industrial and Laboratory Use only.

Fast Selling IP BP Ph Eur EP USP NF JP Analytical Reagent FCC Food Grades of Chemicals by Anmol Chemicals

Ammonium Persulfate --- Acetic Acid Glacial --- Aluminum Chloride --- Ammonium bicarbonate --- Benzyl Alcohol --- Butylated Hydroxyanisole --- Butylated Hydroxytoluene --- Boric Acid --- Calcium Butyrate --- Calcium Chloride --- Calcium Hydroxide --- Calcium Lactobionate --- Calcium Saccharate --- Carbamide Peroxide --- Calcium Oxide --- Calcium Sulfate --- Chromic Chloride --- Fumaric Acid --- Magnesium Butyrate --- Magnesium Chloride --- Magnesium Sulfate --- Malic Acid --- Maleic Acid --- Manganese Chloride --- Manganese Sulfate --- Octyldodecanol --- Oleic acid --- Phenylethyl Alcohol --- Propylene Carbonate --- Potassium Hydroxide Pellets --- Potassium Alum --- Selenious Acid --- Sodium Acetate --- Sodium Bromate --- Sodium Selenite --- Sodium Perborate --- Sodium Hydroxide --- Sodium Sulphate --- Sodium Sulfide --- Sodium Thiosulfate --- Urea --- Zinc Chloride --- Zinc Sulphate ---

Cellulose Acetate

IP BP Ph Eur USP NF Grades Manufacturers